April 21, 2020

April 21, 2020

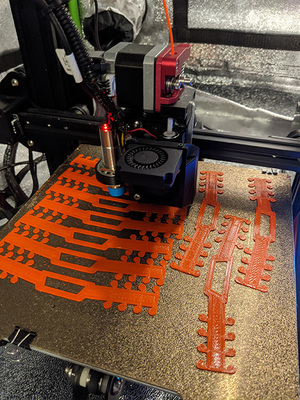

Matt Dalrymple, an information systems technician with Mayville State University Information Technology Services, has been putting his technological expertise to work to aid in the shortage of Personal Protection Equipment (PPE) during the coronavirus pandemic. To date, he’s used his 3D printers to produce more than 150 ear relief bands, which are used to help relieve pressure on the ears caused by medical mask straps; and more than 50 face shields.

With the huge demand for PPE in hospitals, clinics, and other health care organizations across the United States, people in the 3D printing community have been working hard to do what they can to assist in their local communities. In some cases, the PPE items have been shipped to out-of-state locations.

“There is a huge need for PPE for front line workers and those who are at a higher risk of contracting COVID-19,” said Matt Dalrymple. “I want to do what I can to help get us through this unfortunate situation.”

“There is a huge need for PPE for front line workers and those who are at a higher risk of contracting COVID-19,” said Matt Dalrymple. “I want to do what I can to help get us through this unfortunate situation.”

So far, the PPE Matt has produced has been donated to an area critical access facility, first responders, and to a facility that cares for the elderly. He’s also given a small number of ear relief bands to individuals who are in the “high risk” category and who have requested his help.

Matt has three 3D printers set up to print the ear relief bands and one that is set up primarily for face shields. He says these machines can be quickly and easily changed up to print different items if needed.

Photo Captions

Top: Matt Dalrymple is using his 3D printers to produce ear relief bands. The bands are used to relieve pressure caused by medical mask straps. Here you can see production in progress.

Bottom: A batch of ear relief bands produced by Matt Dalrymple is packaged and ready to deliver to those in need of PPE during the coronavirus pandemic.